Fighting Ebola with novel spore decontamination technologies for the military

Christopher J. Doona1*, Florence E. Feeherry1, Kenneth Kustin2, Gene G. Olinger3, Peter Setlow4, Alexander J. Malkin5 and Terrance Leighton6 1U.S. Army Natick – Soldier RD&E Center, Warfighter Directorate, Natick, MA, USA 2Department of Chemistry, Emeritus, Brandeis University, Waltham, MA, USA 3National Institute of Allergy and Infectious Diseases, Integrated Research Facility – Division of Clinical Research, Fort Detrick, MD, USA 4Department of Molecular Biology and Biophysics, University of Connecticut Health Center, Farmington, CT, USA 5Biosciences and Biotechnology Division, Physical and Life Sciences Directorate, Lawrence Livermore National Laboratory, Livermore, CA, USA 6Children’s Hospital – Oakland Research Institute, University of California San Francisco - Benioff, Oakland, CA, USA

Recently, global public health organizations such as Doctors without Borders (MSF), the World Health Organization (WHO), Public Health Canada, National Institutes of Health (NIH), and the U.S. government developed and deployed Field Decontamination Kits (FDKs), a novel, lightweight, compact, reusable decontamination technology to sterilize Ebola-contaminated medical devices at remote clinical sites lacking infra-structure in crisis-stricken regions of West Africa (medical waste materials are placed in bags and burned). The basis for effectuating sterilization with FDKs is chlorine dioxide (ClO2) produced from a patented invention developed by researchers at the US Army Natick Soldier RD&E Center (NSRDEC) and commercialized as a dry mixed-chemical for bacterial spore decontamination.

In fact, the NSRDEC research scientists developed an ensemble of ClO2 technologies designed for different applications in decontaminating fresh produce; food contact and handling surfaces; personal protective equipment; textiles used in clothing, uniforms, tents, and shelters; graywater recycling; airplanes; surgical instruments; and hard surfaces in latrines, laundries, and deployable medical facilities. These examples demonstrate the far-reaching impact, adaptability, and versatility of these innovative technologies. We present herein the unique attributes of NSRDEC’s novel decontamination technologies and a Case Study of the development of FDKs that were deployed in West Africa by international public health organizations to sterilize Ebola-contaminated medical equipment. FDKs use bacterial spores as indicators of sterility.

We review the properties and structures of spores and the mechanisms of bacterial spore inactivation by ClO2. We also review mechanisms of bacterial spore inactivation by novel, emerging, and established non-thermal technologies for food preservation, such as high pressure processing, irradiation, cold plasma, and chemical sanitizers, using an array of Bacillus subtilis mutants to probe mechanisms of spore germination and inactivation. We employ techniques of high-resolution atomic force microscopy and phase contrast microscopy to examine the effects of γ-irradiation on bacterial spores of Bacillus anthracis, Bacillus thuringiensis, and Bacillus atrophaeus spp. and of ClO2 on B. subtilis spores, and present in detail assays using spore bio-indicators to ensure sterility when decontaminating with ClO2.

Results – Field Decontamination Kits in the Ebola crisis

Emerging and re-emerging viral infectious diseases have been identified as a major threat to human health, and the current outbreak of EVD has impacted a large part of Western Africa. Conventional procedures for the decontamination of equipment during a filovirus outbreak rely on the use of chemical chlorine (bleach, aqueous hypochlorite, OCl-) for decontamination when exiting an isolation/treatment center. Electrical equipment that enters an isolation/treatment center and diagnostic facilities can only be surface decontaminated by aqueous rinses with 0.5–5.0% chlorine bleach solution (household bleach is about 6% OCl-). This procedure is likely not adequate for complete decontamination of the devices, particularly for accessing inside the devices.

Devices such as personal cell phones, computers, and most importantly, expensive medical point-of-care (POC) electronic devices used for clinical assessment of patients in isolation/treatment ward are not sufficiently decontaminated by surface rinses. Some medical diagnostic devices have closed systems internal to the device that may have infrequent but probable contamination that cannot be adequately decontaminated by surface rinses with a chemical decontaminating agent. Often these devices contain valuable internal components that may be recycled after being surface decontaminated. This is extremely problematic for items used in a high hazard environment. For low resource, remote sites, the deployment of traditional decontamination tools is nearly impossible. Often there is limited space for equipment, so another desirable aspect of the FDK method is its compact size and simple disposal routine post-decontamination cycle.

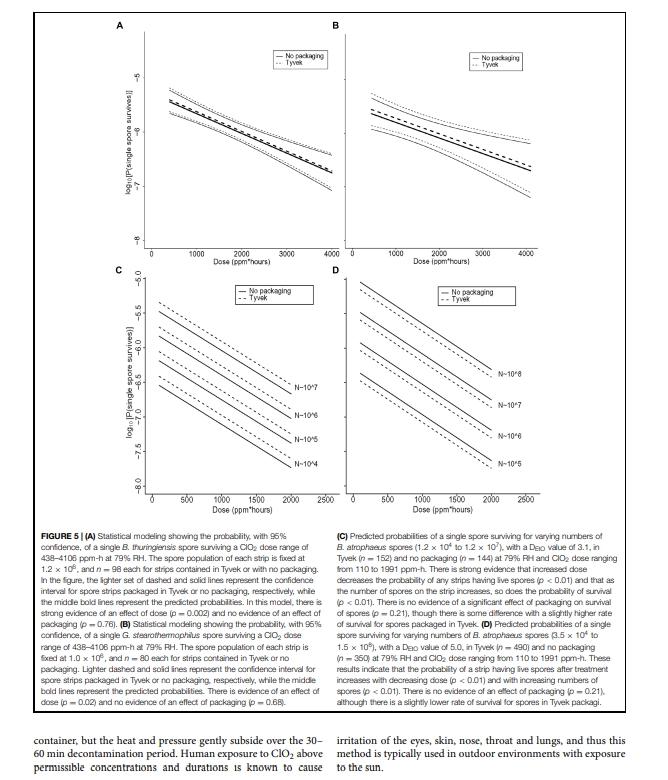

Given the wide use of and acceptability of chlorine bleach solutions in laboratories and in isolation/treatment centers, and the historical use of chlorine dioxide in the decontamination of equipment in the U.S., we decided to adapt a chlorine dioxide method to provide equipment decontamination for deployment in the field in areas of active outbreak. This safe and adaptable method uses a commercially available chemical combination kit called CHEM-CD (ClorDiSys Solutions, Inc., Lebanon, NJ, USA) in which the components are packaged separately and isolated from water to prevent chemical reaction from taking place (Figure 8A). Once mixed together with water, the chemical reduction of sodium chlorite initiates within minutes, and a well-controlled, exothermic reaction takes place that releases chlorine dioxide gas from solution. This reaction is carefully designed to occur inside a closable plastic bag, such that the ClO2 released decontaminates thoroughly the entire interior volume of the bag and all items contained therein, including permeating the interior regions of the electronic medical and other devices inside the decontamination bag. Humidity (≥70% RH) and mild heat and mild pressure accumulate inside the bag from the chemical reaction occurring inside a closed container, but the heat and pressure gently subside over the 30–60 min decontamination period. Human exposure to ClO2 above permissible concentrations and durations is known to cause irritation of the eyes, skin, nose, throat and lungs, and thus this method is typically used in outdoor environments with exposure to the sun.

Adapting this method for field decontamination was ideal, because it is devoid of electrical power sources, uses small quantities of water from available sources, and the low cost of the FDKs, and with the required supplies simple and easy to obtain, store, and handle for ClO2 generation. Specifically, this method was used to develop FDKs (Table 1; Figure 8B) comprising a self-sealable bag (2 or 10 gallon capacity), dry chemical components (Part A and Part B from the commercially available CHEM-CD kit) that react in water to produce chlorine dioxide. The FDK also includes a device to measure water (50 mL tube) and ClO2 indicators of sterility (CD Check Strip, ClorDiSys Solutions, Inc., Lebanon, NJ, USA). In addition, laboratory testing with spore BIs (G. stearothermophilus for steam sterilization from BT Sure, Thermo Scientific, Marietta, OH, USA, and B. atrophaeus for ethylene oxide sterilization from EZ Test, SGM Biotech, Inc., Bozeman, MT, USA as discussed above) showed complete inactivation of spores (sterility) was achieved within 30 min of exposure.

Figure 8A illustrates the procedural steps carried out in utilizing the FDKs. Briefly, the ClO2 indicators are taped to the inner bag to be observed during the decontamination process and the chemical reagents Part A and Part B are placed in a container with water. The item to be decontaminated is placed in the bag near or over the mixture and the bag is subsequently sealed. Within a few minutes the reaction produces condensation (humidity) and yellow ClO2 gas that inflates the bag due to a mild build-up of heat and pressure, although the bag itself does not become turgid. After a minimum of 30 min, the color change of the indicator shows adequate concentration and exposure to ClO2 gas to achieve sterility, and the bag can be opened to release the trapped gas. The equipment can then be removed and surface-cleaned, since the water, ClO2, and inert salts from the spent reaction can be present on the surface. The remaining solution and materiel can be bagged and disposed of according to local policies.

More than 150 FDKs have been deployed for use by global public health organizations during the Ebola outbreaks in Western Africa, which includes Guinea, Sierra Leone, and Liberia, to protect patients and health care personnel. The FDKs have been used to decontaminate laboratory equipment, POC medical devices and personal cell phones. Overall, the performance has been acceptable and only on occasion have the bags leaked gas during the sterilization cycle, thereby requiring longer exposure times to effectuate the color change of the ClO2 indicator strip and signify exposure sufficient to ensure sterility. For the purpose of field deployment, these kits are safe, compact and easy to ship to remote sites that have limited infrastructure and resources available.

master@koreafertilizer.co.kr

Comments

Post a Comment